Tudor House Museum

Steeped in history, the 16th century Tudor House Museum has witnessed many changes in Monarchs and tenants as well as a little movement itself.

As consultants to the museum PHICs were commissioned to oversee the complex 1st floor and loft conservation repair package. .

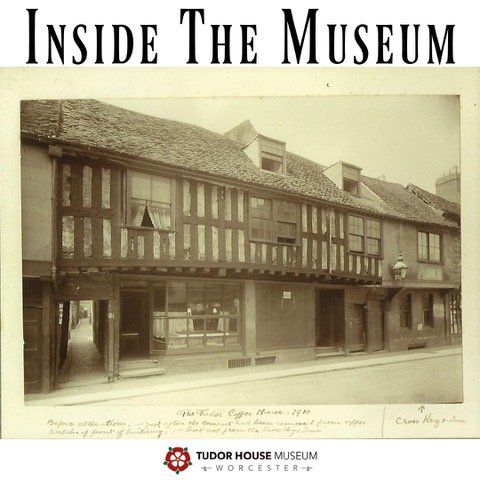

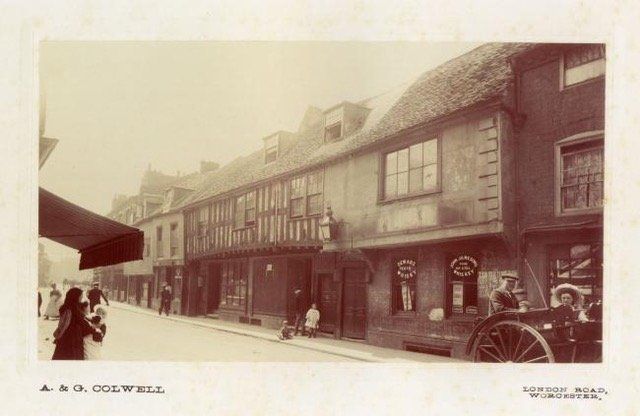

In these early photographs it is clear that two "flat roof" dormer windows were present on the Friar street elevation. These were additions to the original building, the flat roof design indicating they were most likely added in the late 18th or 19th century. They were removed during the mid 20th century and the roof and loft room were again closed-in.

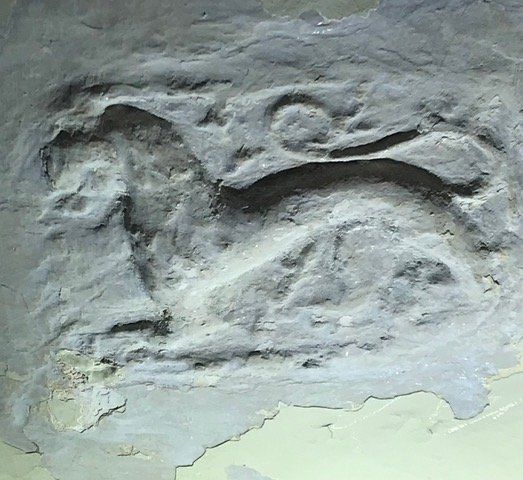

When the dormers were added, the builders had cut through the oak purlins. Timber framed and lime plastered buildings cope with movement very well and the distortions in our black an white Tudor buildings are almost synonymous with the period. Their almost flexible structure is far more suited to such movement than modern day building. However when the dormers were later removed, no support was given to the cut purlins and the roof and building began an exaggerated shift. Over decades the movement split main beams, twisted floor joists away from the fixings and created uncertainty to one of the oldest surviving Tudor strap-work ceiling in Worcestershire.